Heatsink extrusion production technology

1 Put aluminum rod into the furnace

According to the production scheduling requirements and the actual situation of the mold, the aluminum rod with suitable length, correct material, smooth surface without grooves, quality (crystallization, composition, density, no over-burning) must be added. And pay attention to the identification and interval of different aluminum rods. Pay attention to the charging position and chain width, pay attention to close to each other (angle iron resistance, do not use high temperature easy to soften the aluminum material) to prevent plug furnace, pay attention to the handling of the furnace when the aluminum rod does not loose and fall, to prevent personal injury and equipment accidents. Often check the chain, pin, runner, force column and other equipment firm condition. Frequently detect the actual temperature of the aluminum rod, instrument value data (no more than 560 degrees) "In case of long-term shutdown time, it is appropriate to cool down (less than 520 degrees), and check whether the equipment such as fire-spraying gun operation, circulating fan operation and cooling water (water pump) is in good condition."

2 Operation extruder

Extruder operators must pay attention to the following items before formal operation to ensure normal, safety and continuity of production.

(1) Check whether the equipment is working, whether the operating parts of the machine are in place, whether the lubricating condition of the skateboard, whether the stroke switch of the induction device is moving, whether the fastener (screw) is loose, whether the circulating cooling water is turned on, whether the oil level is sufficient, whether the oil temperature is normal, whether the oil pump has no sound, whether the working speed is normal, and whether the action conversion is normal.

(2) Check the condition of the rod furnace (refer to Article 1), check the extrusion center line, check the heating condition of the extrusion cylinder and the fluctuation of the heating instrument. Operation of traction machine, material bed and rear equipment. Whether the various operators are equipped with maintenance hardware tools (die, pad, pressing cake, pressing plate, clamp, hammer, pliers, spanner, screwdriver, thread cutter, crowbar, heat insulation wool top, shaping tool, etc.) are in the fixed position of the work site, and whether the heating furnace or the mold heating furnace is normal. Check whether the various quenching cooling fans are in operation. The various measuring tools are complete and correct.

(3) whether there are any idle personnel at the scene, whether there are any maintenance personnel, whether there are any visiting and inspection personnel, and whether there are any new students, we should dissuade the relevant personnel according to the actual situation on the basis of the principle of safety first, inquire, prompt, prevent, explain, train, guide, demonstrate, etc., and do a good job of keeping secrets when necessary for foreign personnel without leadership. As a whole according to the production schedule, team personnel, pay attention to the connection between the processes orderly.

(4) To know the production contents, production requirements, production order, and make corresponding real data records in the production process, the writing is clear, the production date of the label is clear, and it can be verified, traceable, and can be used for reference. The drawings, forms, data, documents, etc. of the production profile shall be prepared in advance and well known in mind.

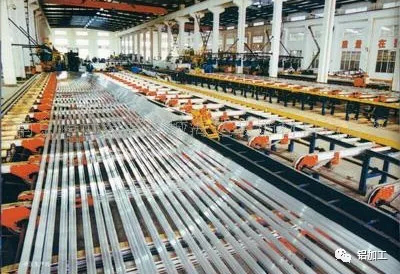

- Aluminium profile stretch

(1) The aluminum profiles on the cooling bed shall not be rubbed, pulled, overlapped, crowded and wound together in the process of feeding and moving and stretching, and a certain interval shall be reserved between each other. The profile with easy bending and long discharge should be treated in time and protected with each other if necessary.

(2) Profile stretch must be cooled to less than 50 degrees (bare hand can hold tightly) before it can be moved to the stretch rack for tensile work. If the temperature is too high, the stretch will not only scald the human body, burn the wool strip, but also appear absolute waste products such as bending, twisting, poor performance and so on because the stress in the profile can not be completely eliminated.

(3) Because the wool strip has the effect of heat-blocking and emission, the material with high requirement on the decorative surface must be turned upside-and-back, so that the heat dissipation is uniform, and the transverse bright spot defects caused by the uneven degree of the heat dissipation are reduced, in particular to a large-wide surface, and the wall-thick section bar is more important.

(4) Pay attention to the stress conditions of small feet, thin teeth, long legs, circular arc surfaces, inclined surfaces, opening, angles, etc., of profiles with high width to thickness ratio, long hanging wall length, large radians, wide wall thickness differences, strange shapes, etc., so as to prevent local or point size deformation, twisting, screw and other defects of the profile, such as small feet, thin teeth, long legs, circular arc surfaces, inclined surfaces, opening, angles, etc.

(5) The stretch amount should be controlled at about 1%. For example, the stretch amount of 25m profile should be straightened and then stretched 25CM, but it must not exceed 2%. In production, the actual situation of profile discharge and various specific requirements (opening size, surface quality, shape size, inner diameter size, wall thickness, extension, etc.) should be adjusted, and the stretch amount which can meet all kinds of specific requirements at the same time should be sought in the contradictory technical requirements. Excessive tensile capacity will result in head, middle and tail size deviation, surface water striped hemp (fish scale) mark, low extensibility, high hardness and brittleness (low plasticity). Too low tensile capacity will make the profile compression strength The degree and hardness are low, even aging (quenching) can not improve the hardness, the profile is easy to arc bending (commonly known as large knife bending).

(6) In order to control the tensile deformation and better control the size change of the whole profile, appropriate special cushions and appropriate methods should be adopted. Especially, open material, arc material, cantilever material, and curved profile should pay more attention to the reasonable and effective use of tensile gasket. If necessary, someone should control the centralization or plug pad in the middle of the drawing profile to ensure that the extension size between the sections of the head, middle and tail meets the requirements of the profile.

4 Aluminum profile saw cutting frame

(1) The material on the conveyor frame shall correspond to the material head and the joint mark, the profiles shall not be rubbed against each other, and the long and short materials shall be well protected against each other. The profile should be straightened back and forth, and the section should not be tilted. Check the package of frame wool and plastic parts, and pay attention to touching and rubbing with exposed iron frame and other sharp hard metals.

(2) Oxidation, spraying, sandblasting, bending circle, punching, material, sawing, packaging, aging, natural wood, and other different post-processing requirements, different materials of profiles, to be framed and transported separately.

(3) Attention shall be paid to the way and method of loading the frame, such as long section material, wall thin material, circular arc material, opening material, solid small section material, sheet material, surface high-requirement material, mutual buckle, self-fastening or difficult-to-be-separated section bar, etc., as well as necessary auxiliary tools, lining paper bushings, and the like. The pad (pad) shall be corresponding to the top and bottom, the arrangement is correct, the interval is appropriate, the quantity is suitable, (some are easy to deform, and the high surface profile shall not be provided with the pad) to bear the weight of the profile and a certain force, and can not be pushed and stacked too much. The profile of the required overhead frame must be stacked overhead.

(4) Pay attention to the position of the profile stacked in the frame to avoid the weight of the two ends, resulting in profile stacking, sliding and other accidents. Pay attention to the sawing speed, sawing surface burr, observe the sawing machine injection size to adjust. Pay attention to the pressing of sawing machine (itinerary, weight). Attention should be paid to sawing operation to avoid personal safety injury accidents. When sawing, it is strictly forbidden to exert force on both sides of the profile, so as to avoid the clamping saw of the profile in sawing, resulting in the occurrence of beating action, which will cause damage and injury to both materials and people in an instant.

(5) Notice that aluminum chips should be blown off, burrs should be scraped off, intervals should be appropriate, hoisting should be safe, and stacked frames should be aligned. The number of stacked frames must not exceed the number of 4 layers specified by the company.

(6) The lifting frame should be lightly lifted, small materials, thin materials, long materials, flat materials, solid small materials and other easily bent materials should be lifted, and pay attention to doubling the length of the fixed scale (sawing, oxidation chuck retention) will make it difficult for the processing and production of the rear working procedure (sawing, oxidation, packaging, hoisting, transportation), and even can not even be processed normally.

5 Aging transport of aluminum profile

(1) During aging, as far as possible, according to the material, thickness, size, hardness requirements, similar performance requirements of the same profile placed in the same furnace for aging treatment. The aging profile should be strictly operated in accordance with the corresponding aging process of the furnace profile, shall not be changed without authorization, and shall not be perfunctory.

(2) Pay attention to observing the circulating fan and circulating cooling water operation, pay close attention to the ignition and heating situation, the heating error in the furnace, the heating speed in the furnace, the heat preservation situation, and pay attention to the safety and sealing of the furnace door.

(3) Pay attention to the leakage of oil and gas, ventilation and safety in high temperature combustion environment.

(4) Pay attention to the drop of the loading and unloading frame and the safe distance between the driving and the material frame.

(5) The stranded personnel in the aging furnace must be strictly prohibited, and the corresponding protection must be done when entering the furnace, and there must be an adult observation and protection outside the furnace. Prevent flammable explosive materials from being carried in the furnace. It is strictly forbidden to be used for baking, heating, sleeping and other unproductive uses.

(6) The profile of different post-processing requirements shall not be combined and the frame shall be transferred to the production department in accordance with the post-processing requirements and the process card (manufacturing summons), respectively. Record the form of each form of the process according to the facts so that it can be checked. The shift will be clear and clear to the face of the shift.